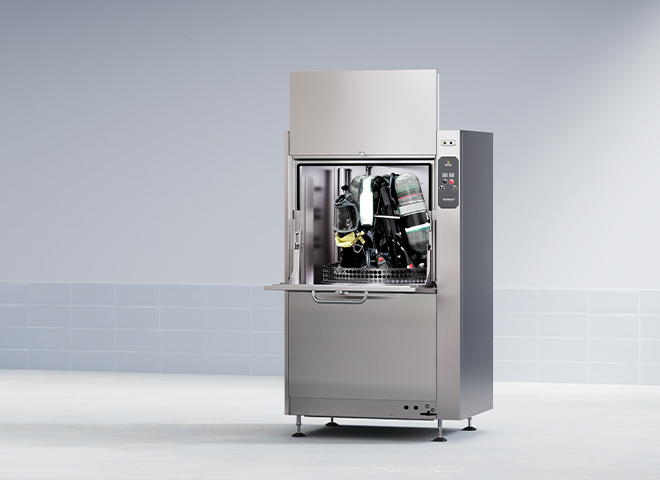

Chris Simpson, Watch Manager and Equipment Officer at Avon Fire and Rescue Service (FRS) in front of the Solo Rescue decon washer.

Chris Simpson, Watch Manager and Equipment Officer at Avon Fire and Rescue Service (FRS), explains how Solo Rescue machines have become integral to its decontamination procedures. The swift and thorough cleaning of equipment helps with the smooth running of its fire stations, whilst prioritising the long-term health of its firefighters:

“Avon FRS was one of the first UK fire services to purchase a Solo Rescue decontamination machine back in 2021. At the time, the industry was beginning to understand more about the importance of cleaning all PPE after fire-related incidents, and it was considered a good investment to help protect our crews from harmful smoke particles. We have since bought four additional machines which are situated in some of our larger stations and at our training facility. The latest was installed in September 2024 as part of the refurbishment of Bedminster fire station in the south of Bristol.

Fast and efficient cleaning

We use the machines mostly for our self-contained breathing apparatus (SCBA) and helmets. They both require the same eight-minute setting, so we tend to leave the machine on the same setting and temperature most of the time. Helmets and SCBA can be loaded in batches which is very easy, and much quicker than cleaning by hand. Once the cycle is finished, they are hung above the sink area so that the straps and linings can fully dry. Personnel from other UK FRSs have visited our facilities to see the machines in action, and they’re often impressed that the kit comes out noticeably cleaner compared to handwashing.

In total, Avon FRS has 225 SCBA sets in service on the fire trucks at any one time and about 25 spare. After an incident, the dirty SCBA and helmets are brought to one of the bigger stations for cleaning, so the Solo Rescue machines are frequently in use. The one at our internal training facility is also heavily used.

The machines are easy to operate, sturdy and robust (virtually firefighter-proof!), and most importantly, they do a great job in keeping our equipment really clean.

Installation and aftercare

The installation process for each machine is very straightforward. You just need access to electricity, water supply and a waste pipe for drainage. This means the machines can be easily integrated into existing fire stations, and of course are very simple to include in plans for refurbished or new facilities. For our recent installation in Bedminster, Rescue Intellitech organised delivery to coordinate seamlessly with the refurbishment fit out.

Once the machines are in place, full training is provided to key personnel. Our contact, Nick Croad, held a training session for me and the other BA technicians, and we were then able to provide simple operating instructions to others in the service. We also have an aide memoire on the side of the machine as a reminder.

Nick comes to service the machines every year. However, if we ever have a problem or a query in the meantime, he is always very attentive and quick to respond.

Clean sir cylinders and harnesses at Avon FRC

The decontamination process

When I first joined the service, after an incident, firefighters would drive back to the station in their dirty gear and the truck and station would stink of smoke for days afterwards. Thankfully, we now have clear guidelines and processes in place to make sure our crews decontaminate as quickly as possible.

Ideally if space allows, fire stations should adopt a red, amber and green zone system for designated contaminated, transition and clean areas. That’s not always possible to create in existing buildings, but new or refurbished ones now are designed this way.

We also have a ‘safe undress’ policy for removing PPE after an incident. Jacket, trousers, boots and gloves are carefully removed, and special wipes are used to clean exposed skin. Then latex gloves are put on before the helmet is removed and the flash hood taken off over the mask and down the SCBA hose. The SCBA mask is the last thing to remove, replaced immediately with an FFP3 mask.

Dirty clothing is then placed in red bags and stored in a separate area of the truck and station for collection and cleaning, while the helmets and SCBA are also bagged and taken to one of our stations for decontamination in the Solo Rescue machines.

We then try to ‘shower within the hour’ using special soap and shampoo for removing contaminants. Together, these are all important steps to help us minimise exposure to harmful particles and keep our crews safe.

Avon FRS was one of the first UK fire services to purchase a Solo Rescue decontamination machine back in 2021… We have since bought four additional machines which are situated in some of our larger stations and at our training facility.

A final word

We have been really impressed with the Solo Rescue machines and the excellent aftercare service provided by Rescue Intellitech. The machines are easy to operate, sturdy and robust (virtually firefighter-proof!), and most importantly, they do a great job in keeping our equipment really clean. I expect we’ll fit Solo Rescue machines into all of our new or refurbished fire stations from now on. Once you’ve tried it there’s no going back!”