A modern decontamination room is crucial for minimizing exposure to hazardous substances such as carcinogens, biohazards, volatile organic compounds (VOCs), polycyclic aromatic hydrocarbons (PAHs), and heavy metals. Leveraging current experience and research, this article outlines key features and strategies for creating a decon room that effectively addresses contamination risks.

What is a decon room and why is it important to have one?

A Decon Room or Decontamination Room is a dedicated facility for cleaning and decontaminating firefighting PPE and equipment after exposure to hazardous substances. Beyond protecting health and preventing cross-contamination, thorough decontamination extends the lifespan of PPE, improves operational efficiency, ensures compliance with standards like NFPA 1850, and builds public trust.

What PPE equipment and gear should be decontaminated?

Firefighting PPE is routinely exposed to a variety of harmful contamination during incident response, which can remain embedded on the surface and within the fabric if not properly removed. Over time, failure to clean gear effectively can increase the risk of long-term exposure and compromise the protective qualities of the equipment.

The era of walking around covered in soot and grime as a badge of honor is over–today, clean is the new standard.

The golden rule is that after every emergency response where the PPE is contaminated, the PPE must be thoroughly decontaminated. The era of walking around covered in soot and grime as a badge of honor is over–today, clean is the new standard.

Studies show that contaminants can infiltrate every layer of PPE, from bunker gear to station uniforms1. With exposure routes including inhalation, ingestion, and skin absorption (dermal exposure), it is critical to ensure that no part of the gear is left unwashed. Key items that require decontamination include:

- PPE: SCBAs, air bottles, face masks, helmets, boots, gloves, bunker gear (also referred to as turnout gear), and station uniforms.

- Tools and Equipment: Any items exposed during emergency operations.

What Equipment and Facilities Are Essential for Cleaning Contaminated Gear Thoroughly?

Thorough cleaning and decontamination require purpose-built facilities and appropriately customized cleaning equipment tailored to specific needs. Without the proper equipment, it is impossible to achieve the results necessary to fully protect the people working in the station. The following equipment and facilities are highly recommended for all modern fire stations.

Washing and decontamination equipment

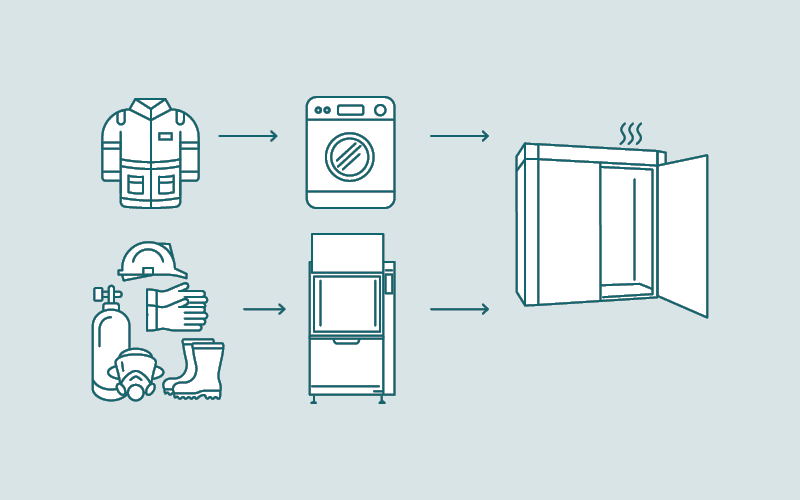

- Washer extractors – For washing bunker gear

- Residential-style washing machines – For washing station uniforms (Washing of personal clothing should not be conducted in the same washing machines used for decontamination due to the risk of cross-contamination)

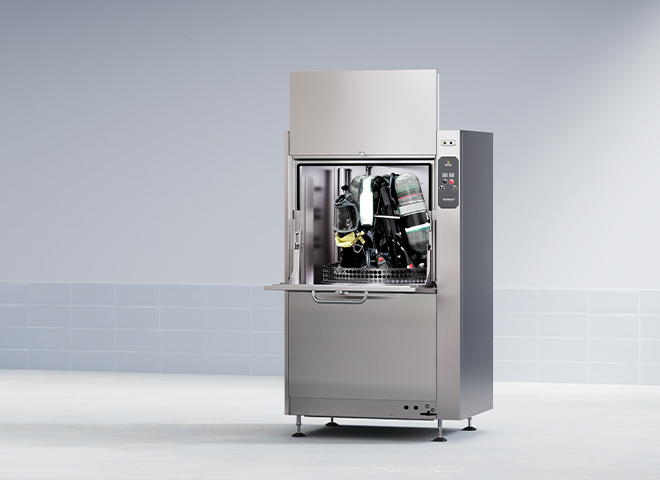

- SCBA and PPE washers (gear washers) – For washing SCBAs including air-cylinders and harnesses, boots, gloves, helmets and tools

- Industrial dryers (drying cabinets) – For gentle and efficient drying that prolongs the lifespan of the equipment

- SCBA detergent – For cleaning SCBAs with a detergent that meets NFPA requirements for proper pH levels and material safety

Bunker gear should be cleaned in a extractor, while boots, gloves, SCBA, and helmets should be decontaminated in a gear washer.

Complementary facilities

- Storage for Contaminated Gear – Temporarily store decontaminated gear

- Work sink and scrubbing stations – For manual cleaning of smaller items and hard-to-reach areas of equipment

- Prewash soaking tub – For pre-soaking of turnout gear/bunker gear

- Hygienic Ventilation System – Ensures proper airflow and prevents contaminants from lingering in the room.

- Drying Rooms – Controlled humidity settings to expedite drying while avoiding degradation of the gear

- Storage for Cleaned Gear – To separate decontaminated gear from contaminated items

- Special Waste Disposal Systems – For collecting, filtering and safely disposing wastewater, residual contaminants, and other hazardous materials

- Secondary Shower Areas or Hygienic Entry/Exit Stations – To decontaminate personnel after cleaning tasks